“Nature has invented most of the solutions we might need” – an interview with Maciej Głowacki

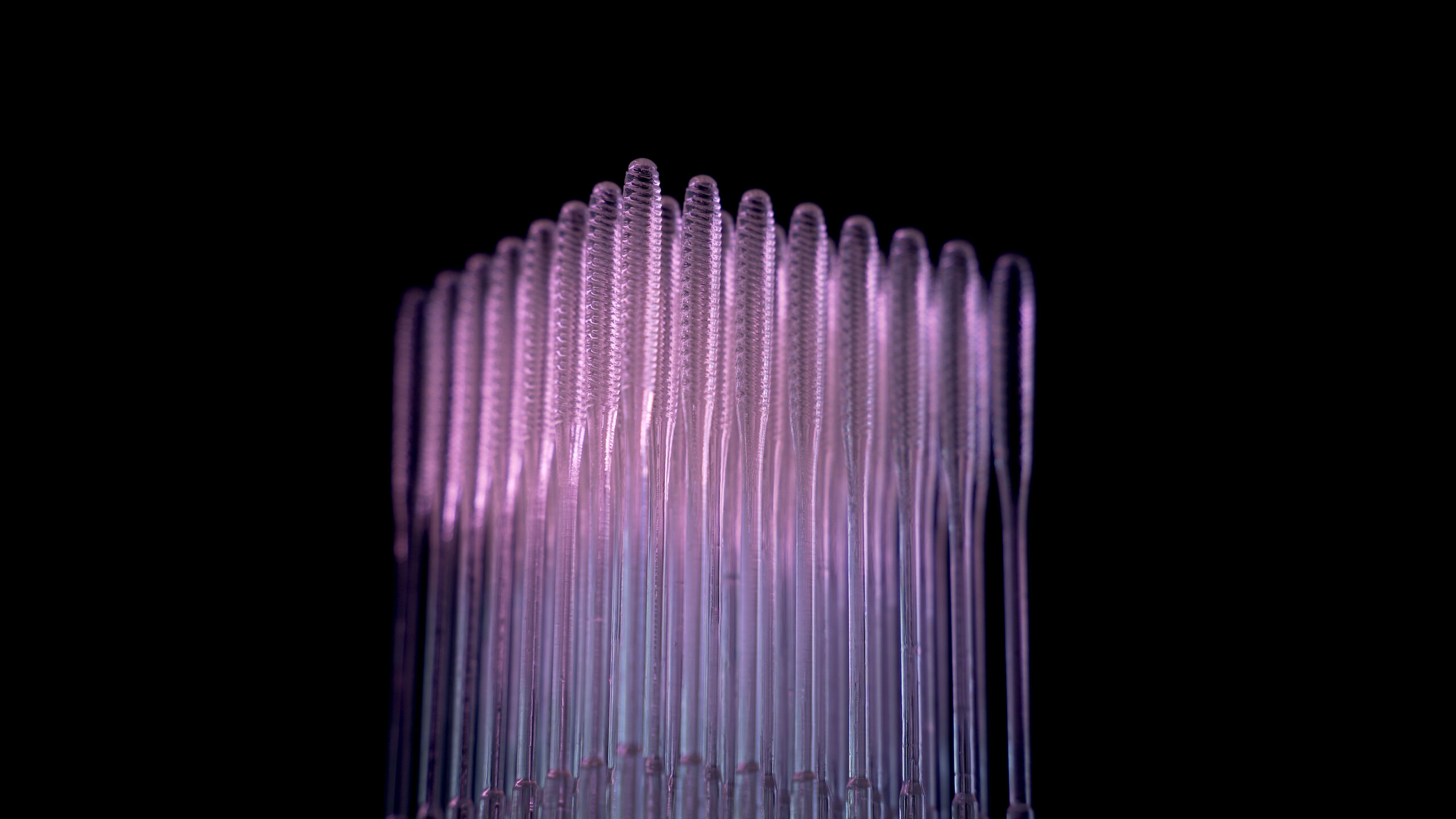

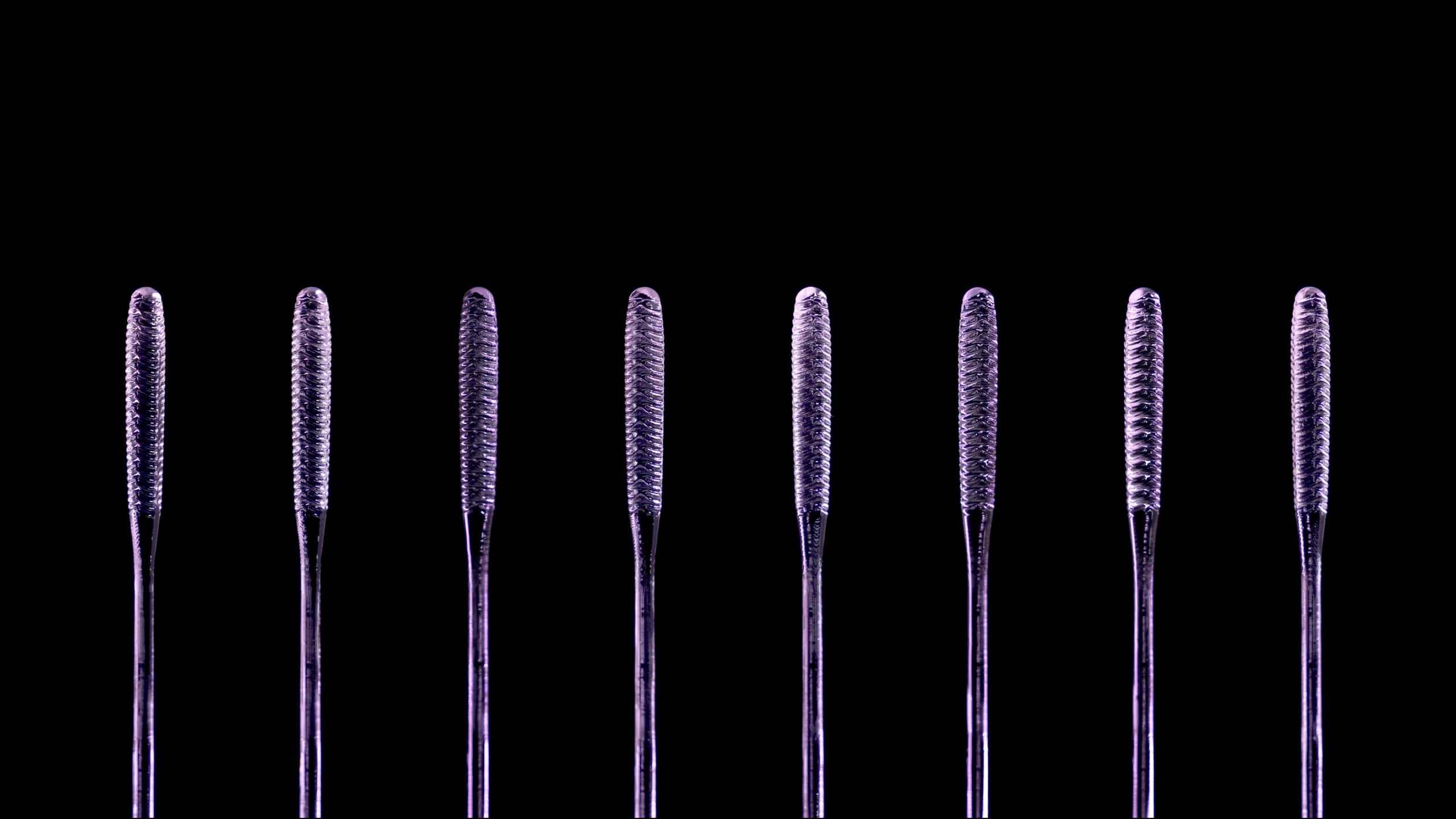

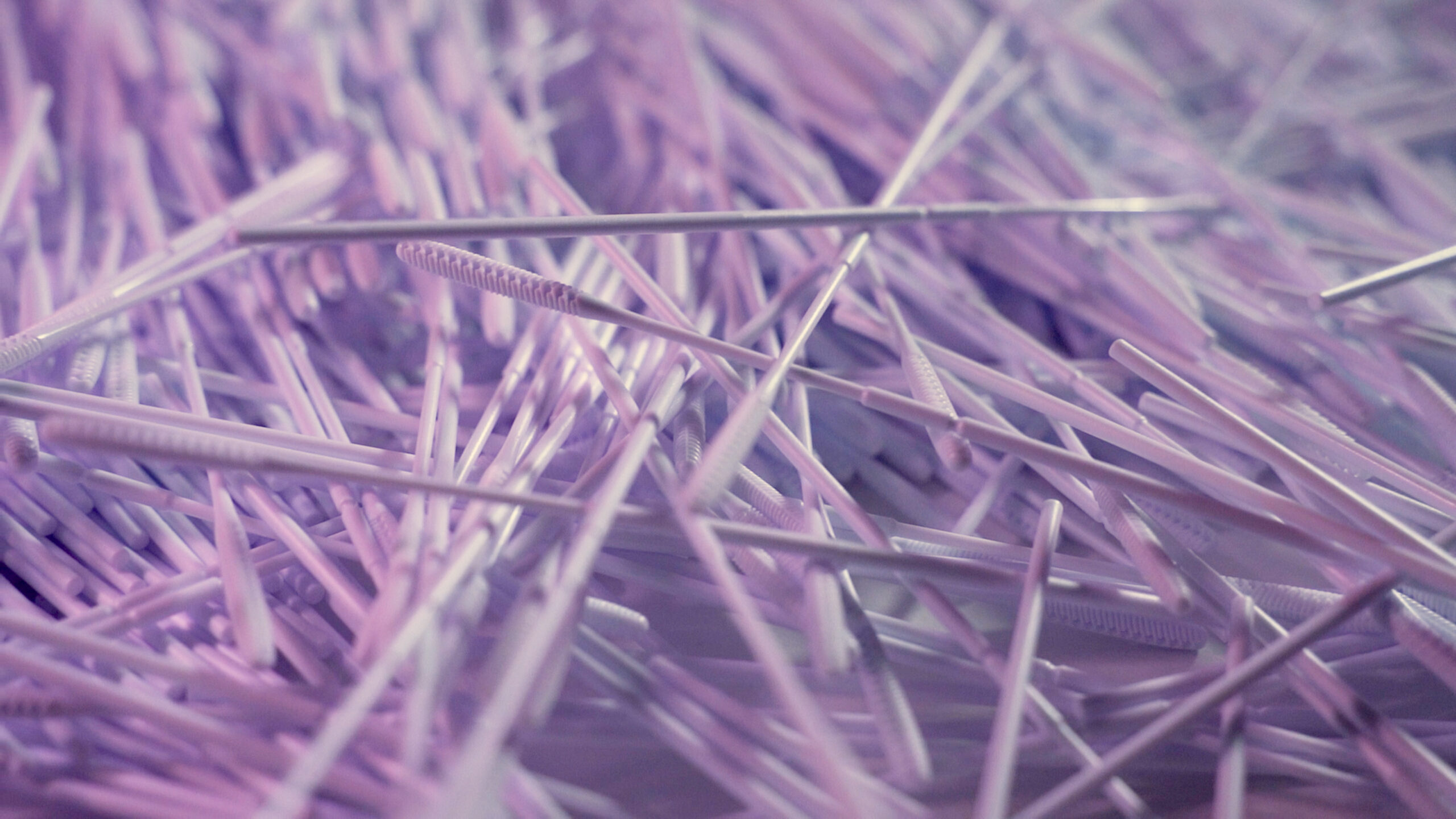

We talk about “returning to nature” as a design strategy, the modern Hippocratic Oath for designers and the challenges facing design in times of climate catastrophe with Maciej Głowacki, who, in response to the medical crisis caused by the COVID-19 epidemic, developed one-piece, eco-friendly swabs with a shape inspired by the tongue of a hummingbird. The designer was awarded the 2nd place in the make me! competition at the Łódź Design Festival 2022 for the CRN_01 “Hummingbird” swabs.

Bartłomiej Jankowski: At this year’s make me!ncompetition at the Łódź Design Festival, you were awarded a distinction for your project CRN_01 “Hummingbird” swabs. When I read its description, I thought to myself that it was such an “intervention design”. Let’s go back to that moment for a while: it’s 2020, the beginning of a global epidemic, a social panic. And you just rolled up your sleeves in cold blood to come up with a design that would solve the medical crisis?

Maciej Głowacki: I like the term ‘intervention design’ – acting with a specific pressing problem in mind. On an everyday basis, I work for a company that deals extensively with new technologies and 3D printing, such as rapid prototyping, and rapid tooling. It is the rapid intervention that is at the heart of this technology – with 3D printing, you can instantly realise the prototyping process and move on to mass production. This was also the case with the swab project. During the pandemic, there was a fantastic rush of 3D printers, professional and amateur ones, who printed the visor bands on their own machines. Together with Sygnis, the company I work for, we joined this action – I myself also designed visors optimised for faster production at the time. Every day, and also at night, we printed dozens of pieces, which we sent to hospitals reporting shortages. Upon achieving stable production we moved on, recognising that we had the knowledge and capacity to do more. We often heard from medical professionals that there was a shortage not only of masks or visors, but also of more advanced diagnostic equipment, such as swabs. At first, this topic was a closed book to me, so I approached it with curiosity, wanting to learn as much as possible and gain as much expertise as possible.

BJ: At the time, however, you did not print the swabs in the form we are mostly familiar with. In fact, you designed them from scratch – they were assembled from a single material, produced in a single step.

MG: The main idea was to simplify the production process. Commercially available swabs are produced in two stages, for which you also need specialist production lines. Under pandemic conditions, it was not possible for us to produce them quickly and locally on our own. On the other hand, problems with supply chains, especially of specialist products, became an everyday phenomenon. In Poland, at the peak moments of the pandemic, we had tens of thousands of infections diagnosed per day, which would have meant doing more than 100 000 tests per day. We therefore wanted to produce as many such products as possible as quickly as possible, so that they would be available locally, wherever needed. Our first instinct was, of course, 3D printing. For all its advantages, however, this technology has a rather limited production throughput – we could be talking about hundreds, not tens of thousands of units per day. Therefore, we had to abandon printing in favour of injection moulding. The biggest challenge was to design the swab so that the injected structure itself could fulfil the task of high-tech flocs – to take as much sample as possible and then allow for as many tests as possible.

BJ: How did you come up with the idea that hummingbirds sipping nectar with a long tongue might be the answer?

MG: It was a coincidence. You can sit for hours working with sheets of paper, models, prototypes, and in the end the whole process often comes down to sheer luck after all. I came across a video on YouTube – a recording by Anand Varma, a photographer for “National Geographic” – which showed hummingbirds drinking nectar in slow motion. When I saw the mechanics of the process – a long tongue taking up food – the resemblance was striking to me. I remember spending an entire night googling for scientific publications, which at first was a bit like walking in the dark without being convinced of the validity of the chosen path. Finally, I came across a study from the University of Washington analysing hummingbird tongues in detail. I felt that, based on the knowledge I had gained, I could transfer a principle that works so well in nature to human use.

CRN_01 “Hummingbird” Swabs, design: Maciej Głowacki / from designer’s archive

CRN_01 “Hummingbird” Swabs, design: Maciej Głowacki / from designer’s archive

CRN_01 “Hummingbird” Swabs, design: Maciej Głowacki / from designer’s archive

BJ: Let’s talk about it as a certain design strategy. Was this the first time you took on this form of design

MG: If you’re asking about biomimetic design – it definitely was. I had entertained myself with generative jewellery inspired by anemones before, but they were more of a formal academic exercise. Still, I’ve always been fascinated by projects like the kingfisher-inspired Shinkansen bullet train, the American B-2 hawk’s beak bombers, or even the examples cited by Papanek in “Design for the Real World.” I’ve also recently come across a sensational idea from 2010. – the use of a particular type of a slime mould to delineate connections for Tokyo’s rail network. I’m fascinated by nature, which has already come up with majority of the solutions we might need. On the other hand, it saddens me that we are not sensitive enough to devote ourselves to finding these analogies.

BJ: Recognizing these solutions and… copying them? That might sound a bit pejorative. What word would you use to describe it?

MG: I think adaptation would be a better term. And inspiration. Nature is essentially a knowledge base – it has had hundreds of thousands of years to reprototype everything and arrive at universal solutions. Regardless of whether we are talking about structures, or even the mechanisms of self-organization of life at different levels.

BJ: On the one hand, this is a very rational approach, referring to the laws of nature. And on the other hand – I think it’s a bit of romantic thinking: as mankind we have gone the wrong way, we have violated the network of primary relationships, we have messed up. Will a “return to nature” be the answer?

MG: I think so. This trend is already present in many forms. Corporate green-washing unfortunately invests millions of dollars in developing solutions that are often superficial or misguided. And on the other hand, we are pushing the limits of cognition – cases such as the recent high-profile research on converting the hydraulics of dead spiders’ limbs into grippers show that the R&D direction is set and we have ready-made solutions in front of us. All we have to do is figure out how to transfer them to design problems we know.

BJ: What does the design work consist in in such a case? We have some mechanism or structure that we have to translate into technologies we know. That’s quite a challenge, isn’t it?

MG: It definitely is, but I’m of the opinion such a challenge that consists in understanding is present at the very core of design. It encompasses understanding the material you are working with, understanding the needs you are trying to meet, or understanding the user who will be using the design. The worst mistake of a designer, in my opinion, is to assume that one has absolute and definite knowledge about something. I much prefer the perspective of humility. Every design process should begin with the process of gaining insight: using both the knowledge available in the world’s largest library, which we have at the click of a button in those funny pixels in front of us, and the knowledge provided by experts. The objective is to gather as much information as possible and synthesize it creatively.

BJ: When I think of biomimetics, I think of new technologies, laboratories – of something very modern. On the other hand, “mimesis” is a very old aesthetic category that is an expression of some primary need….

MG: In my first Polish language class in high school (with prof. Żabińska, to whom I would like to extend my warmest greetings) I wrote down “mimesis – imitation” as the first definition. And then, of course, we moved on to Greece and Aristotle….

BJ: Yes, I did. I don’t have the scenery of late-modern laboratories before my eyes.

MG: We can come across unusual references to imitation in every age. I recently visited an exhibition about Mies van der Rohe’s architecture in the context of nature (among others). It showed books by Raoul Heinrich Francé, a French botanist considered the author of the concept of “biotechnics,” the prototype of biomimetics. I was absolutely fascinated when I saw in “The World of Plants” written by him and published in 1912 the drawings of cross sections of power cables juxtaposed with cross sections of stems or a comparison of maple seeds with ship propeller blades. Picasso reportedly commented on the Lascaux drawings with the exclamation that we had not discovered anything new in art since the Stone Age. In the case of design, we can go back even further….

BJ: How, then, would biomimetics differ from these drawings?

MG: Biomimetics would be an attempt not only to be inspired by a feeling, an impression, but also to dive deeper into the subject – to understand why the actually falling maple “noses” go into this funny spinning motion. The starting point is to look at the phenomenon with childlike fascination and go one step further. Not just to marvel at the action itself, but to try to understand it. To ask oneself if there might be an answer in it.

BJ: Does this mean that nature is smarter than us?

MG: Yes, indeed! I have no doubt that nature is much smarter and would do perfectly well without us, as it has done for millions of years. I don’t think human impact is best for her, and I’m not sure it’s best for ourselves either. At this point in history, we can finally focus on taking responsibility, more conscious design action. Coming back to the swabs, this is why, among others, I was keen to integrate these disposable products into the assumptions of the circular economy, which was not possible until now. In this case the design was created from a single material, so after the test it can be sterilized and recycled again.

CRN_01 “Hummingbird” Swabs, design: Maciej Głowacki / from designer’s archive

CRN_01 “Hummingbird” Swabs, design: Maciej Głowacki / from designer’s archive

BJ: In your work you combine different fields, such as science with design and new technologies.

MG: I’m the son of two computer scientists, so I had always been prepared to follow in their footsteps and work in the area of science, like math, chemistry, or physics. My first study choice was nanostructure engineering, a macro course at the Faculties of Physics and Chemistry at the University of Warsaw. I was fascinated by the possibility of looking at life at the nanoscale, where everything can be counted, understood. However, amidst the reality of scientific work, while pouring of things from one test tube to another in the laboratory, I was missing something more creative. I was looking for a path for myself at the time. One day my friend asked spontaneously: “And why not design?”. At that time I had no idea what design or designing was – the first association was making pretty furniture or posters. So I did some research and it turned out that this direction combines the need to analyse phenomena with turning them into a creative process – and thus obtaining a new value.

BJ: You had this first skill already. And you combined it with an added value of creativity.

MG: The possibility of expression. Creating value that can be used by others. I really like this motive: design as an aid that can be offered to the world. It is in our hands. If we had been able to have such a negative impact on the nature around us, it means that we quite huge amount of agency. Why not start acting consciously, responsibly then? In addition, I have always enjoyed learning, I have had an insatiable hunger for knowledge that can be absorbed from the reality around us. The design seems like an ideal, productive channelling of this curiosity.

BJ: What other challenges do you face? What questions would you like to find answers to?

MG: The topic of designers’ responsibility is very close to my heart – after all, we make decisions that can have a significant impact on others. Products have unquestionable agency- they shape habits, behaviours, ways of thinking. I do not want to generalize, but I think that at this point the awareness of this responsibility – with all the new models of cars, chairs, or tables – is quite low. After all, we live in a capitalist system where profit and expanding catalogue offers count more than solving real problems. I think this is one of the biggest challenges: as you can design literally anything – from three-dimensional, tangible products to interaction design, UX – designers shape the world around us. That’s why, in times of global climate crisis and progressive socio-systemic crisis, a huge part of the responsibility lies with us. If we continue to produce more designs of repetitive products just for market profits, we are unlikely to make a real difference.

BJ: Is it against the ethics of the designer?

MG: If there is a Hippocratic Oath for doctors, why don’t we designers also have a commandment to “do no harm”? Why doesn’t anyone teach us responsibility, criticize us for duplicating existing solutions, naive “design” of new packaging for old functions? Recently, this topic of responsibility has become particularly tangible to me yet in connection with another design intervention. Together with the company where I work, we became very strongly involved in a project to help Ukraine. First, we bought a bus to take some 20 3D printers and 400 kg of material to Ukraine so that Ukrainian printers could produce the missing equipment on the spot, including Israeli bandages, which are simple tourniquets used for wounds. Later we decided to go one step further. It turned out that people from different parts of the world started to 3D print tactical stasis for Ukrainians en masse without any knowledge on these products. Therefore, later they were lingering in hundreds in boxes in Ukraine because the shipped equipment had not been tested in any way, it had been created with no awareness of the necessary mechanics, and the materials were inadequate. The products were not fit for purpose, and they brought more risks than benefits. It was frightening for me to see how recklessly one can act, naively wanting to help. That’s why we took matters into our own hands. During two or three months we designed and prototyped tactical stasis, and we also held meetings with field medics, paramedics, and military officers. Before we sent the first batches to the front, we had completed at least eight iterations of the product for internal testing. We had also performed full laboratory material tests to check the strength, weather resistance, and clamping uniformity. Only after the whole process could the design be considered ready for shipment to those in need on the front lines. Initial tests on the Ukrainian side were successful. As of this moment, we have already shipped more than a thousand pieces to Ukraine, we are constantly producing more. I know of three lives saved by this product. That’s a lot for a few pieces of plastic.

BJ: So, as with the swabs you asked yourself the question: “How can I help?” I also wanted to ask whether make me! helped you in any way. How was the swab design received?

MG: make me! is such a prestigious competition with industry-experienced judges that the very fact of being awarded gave me a great deal of confidence. People with authentic authority chose my idea and decided that it was worth showing it to the world – I took this as a message that my design activity made sense. I reaffirmed my conviction that this was a good life decision and that it is worth continuing on this path. What else is left but to seek and try to create “value”?

Text: Bartłomiej Jankowski, OKK! PR

Maciej Głowacki

A graduate of the Design Faculty at the Academy of Fine Arts in Warsaw, I previously studied at the Faculties of Physics and Chemistry of the University of Warsaw. The background of scientific education allows me to maintain an analytical approach in my design projects. Since 2014, I have been gaining professional experience working for the Polish technology company Sygnis SA.

“For me, design is a vocation. I believe that as designers, we should direct our gaze to regions that do not promise profit or market value. We are to search for genuine needs and answer the yearning present in people.”